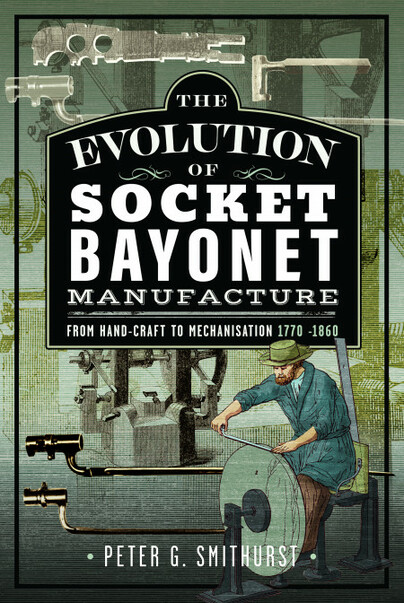

The Evolution of Socket Bayonet Manufacture (Hardback)

From Hand-Craft to Mechanisation 1770 -1860

Imprint: Pen & Sword Military

Pages: 288

Illustrations: 178 mono illustrations

ISBN: 9781036137199

Published: 31st October 2025

(click here for international delivery rates)

Need a currency converter? Check XE.com for live rates

In the case of military muskets and rifles the bayonet was, and still is, an integral part of the ‘weapon system’. There are many excellent books covering the history of the bayonet in its myriad varieties adopted and used by the armed forces of the world. These books provide a wealth of detail on national variations and often include many rare, and in some instances, bizarre bayonets. They focus on the end of the bayonet’s story and do not cover its beginning – the conversion of more or less amorphous pieces of iron and steel into finished products. That is the focus of this publication.

It might be asked why, out of all the bayonets of the world, these three have been selected since at first sight they appear very ordinary and mundane when compared with some of their more ‘exotic’ brethren. However, as with the arms they were fitted to and whose manufacture has been covered in two earlier companion volumes, they are the only bayonets whose manufacture is described in varying degrees of detail in contemporary publications. They also share another kinship since, like the weapons they fitted, the Russian M.1808 is a direct copy, and the Enfield Pattern 1853 bayonet a descendant of, the French M.1777. This bayonet was a major landmark in socket bayonet design. It may be distasteful and not something to be contemplated lightly, but the socket bayonet’s function at the end of a musket was to penetrate the body of an enemy in close combat. Earlier bayonets having a plain mortice or ‘zig-zag’ slot engaging with a stud on the barrel to hold them in place, might easily be removed from the musket by one or other of the adversaries twisting it in the wrong direction. Honoré Blanc’s design, with its medial locking ring, prevented such accidental removal and became the prototype for many, if not all, socket bayonets which followed through to the end of the 19th century.

Peter Smithurst’s The Evolution of Socket Bayonet Manufacture from Hand Craft to Mechanisation 1770-1860 has opened up a new dimension in the collectors’ world. In the same way that the Haynes Owner's Workshop Manual supports the automobile enthusiast this excellent publication enlightens the bayonet devotee. Many such individuals admire the appearance and history of such artefacts. Others even covet, collect, classify and cosset the weapons themselves. Few, if any, research the technological processes behind the items. Publications, until now, have informed this reality. Peter’s work has now filled the gap. Research based on primary sources, backed with huge expertise on industrial and technical subjects, has provided a well illustrated, easily readable, layman’s guide to socket bayonet manufacture. Of particular advantage, for non-linguists, is the translation of French and Russian descriptions that would otherwise be out of reach. The detailed comparison of French, Russian and English processes allows for a good understanding of their differences. The in-depth coverage of the Pattern 1853 bayonet is particularly noteworthy. Original drawings and illustrations have been analysed and enhanced by Peter’s own clear diagrams and explanations. Obscure technical terms have been defined, and, in some cases where descriptions are vague, Peter has formulated an interpretation.

Graham Priest - Bayonet collector and a prominent expert

As a collector of bayonets since the mid 1950s, with a specialist interest in socket bayonets since the early 1970s, I am grateful to Peter for enhancing my knowledge of the subject. Several details of construction that have puzzled me for decades are now clear. I have no hesitation in recommending this publication to others.

About Peter G. Smithurst

Peter G Smithurst graduated in Chemistry and Biochemistry in 1968 spending several years as a research chemist before pursuing his passion for industrial and technological history, moving in to museum work.

Peter was appointed Assistant Curator of the Industry and Technology section of Sheffield City Museums in 1975 including the planning and opening of the Kelham Island Industrial Museum in 1982 leading to a promotion to Principal Keeper, Industry and Technology. In 1994 Peter was appointed Assistant Curator of Artillery at the Royal Armouries Museum at Fort Nelson before transferring to the Royal Armouries in Leeds for its opening in 1996.

In 2001, Peter became the Executive Director at the American Precision Museum in Windsor, Vermont housed in the Robbins & Lawrence factory where much of the technology for the mechanised manufacture of firearms, including the Enfield 1853 rifle, had been developed before finally returning to the Royal Armouries in 2002 retiring in 2009 as Senior Curator of Firearms. Just prior to retirement Peter was appointed Visiting Research Fellow at the University of Huddersfield resulting in a PhD from the School of Engineering and Computing in 2020 for a study of the manufacture of the Pattern 1853 Enfield Rifle-Musket and was subsequently elected Fellow of the Society of Antiquaries of London in 2021.